This live, online training course with live instructors consists of 6 classes, 3 hours each, over two weeks.

GibbsCAM Intermediate Turning - Live Online

Take your GibbsCAM skills to the next level.

In this course, we explore the full range of capabilities offered by the GibbsCAM turning module. You’ll learn a variety of machining strategies to create more efficient operations, reduce cycle times, and extend tool life. Our instructors bring decades of real-world mill-turn experience and are eager to share their expertise with you.

Our live online format delivers a true classroom-style experience, with full two-way screen sharing between students and instructors. You can ask questions, get instant feedback, and follow along step-by-step—all from anywhere, whether you’re at the shop or learning from home.

Prerequisites

We recommend starting with the GibbsCAM Essentials class before progressing to Intermediate Turning. However, depending on your experience with GibbsCAM, you may already have the foundational knowledge required for success. If you find this course too advanced, consider revisiting the GibbsCAM Essentials class to build the programming skills essential for this course.

Please reach out to us at info@camco-ne.com for help finding the right class for you.

Recommended hardware:

- 2 monitors are recommended. One to run GibbsCAM, the other to display the instructor’s screen.

- Note: the system we use does not have a dial-in option. Speakers and a microphone or headphones with microphone will be required.

- High-speed Internet Connection.

- Windows 10 or 11 (with all available Windows updates).

- Intel: Core i9, or i7 with four or more cores or AMD: Ryzen or Threadripper.

- 16GB RAM

- A quality Nvidia or AMD (ATI) 3D accelerated video card with 2+ GB of video memory with the latest drivers installed.

- Send setup-related questions to: support@camco-ne.com

Software

A 30-day GibbsCAM timed license will be provided.

Topics Covered Include:

- Overview of the mill-turn interface

- Import solids and define stock

- Introduction to solid modeling and extracting geometry from solids

- Create high speed roughing strategies using VoluTurn and Prime Turn

- Advanced threading: tapered, variable pitch, scroll threading, thread clipping

- Milling using polar and cylindrical interpolation

- 4-Axis radial milling processes

- Transition from mill-turns to double spindle multi-task machines

- Eccentric turning

- Advanced turning features: notch ramp, peck turn, advanced approach/retract, drill-turn

- Define turning tools and holders in GibbsCAM using solids

- Lathe drilling: counter rotating live tools

- Add cutting data to tools

- Advanced coding options

Accounts

Your Text

Your Text

Your Text

Your Text

Your Text

Your Text

Live Online

Intermediate Turning

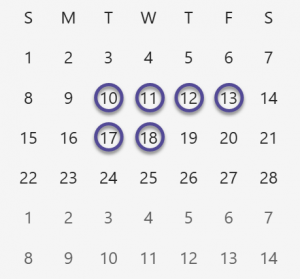

February 10-18, 2026

3 hours per day, 12 pm -3 pm

$1,145