Why Choose GibbsCAM?

Unique User Interface Created for Machinists

GibbsCAM works the way you think. The fully customizable interface makes programming a pleasure.

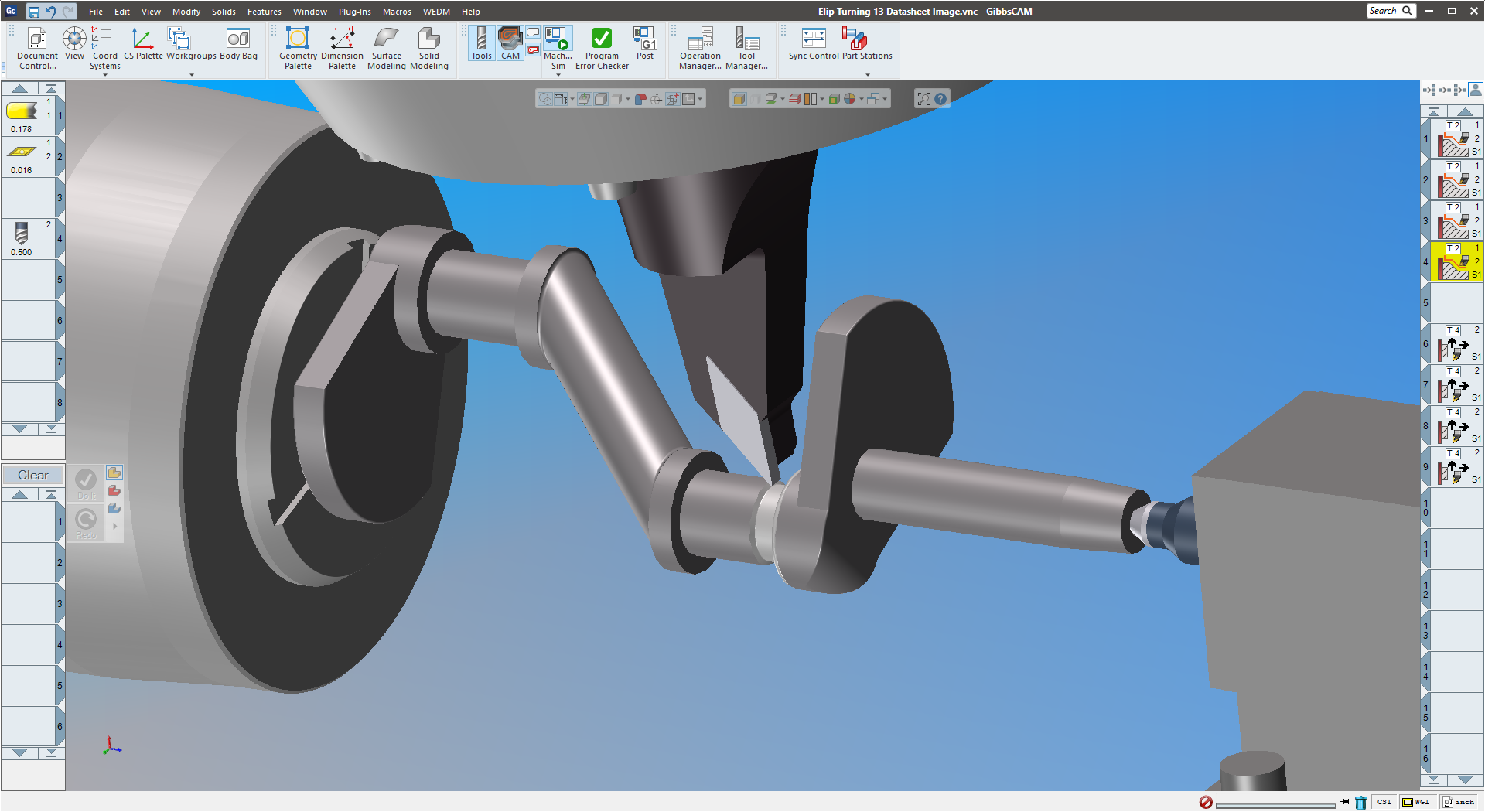

A Single Application for Programming Every CNC

GibbsCAM grows with you. Simple and complex machines all programmed with one, easy to use interface.

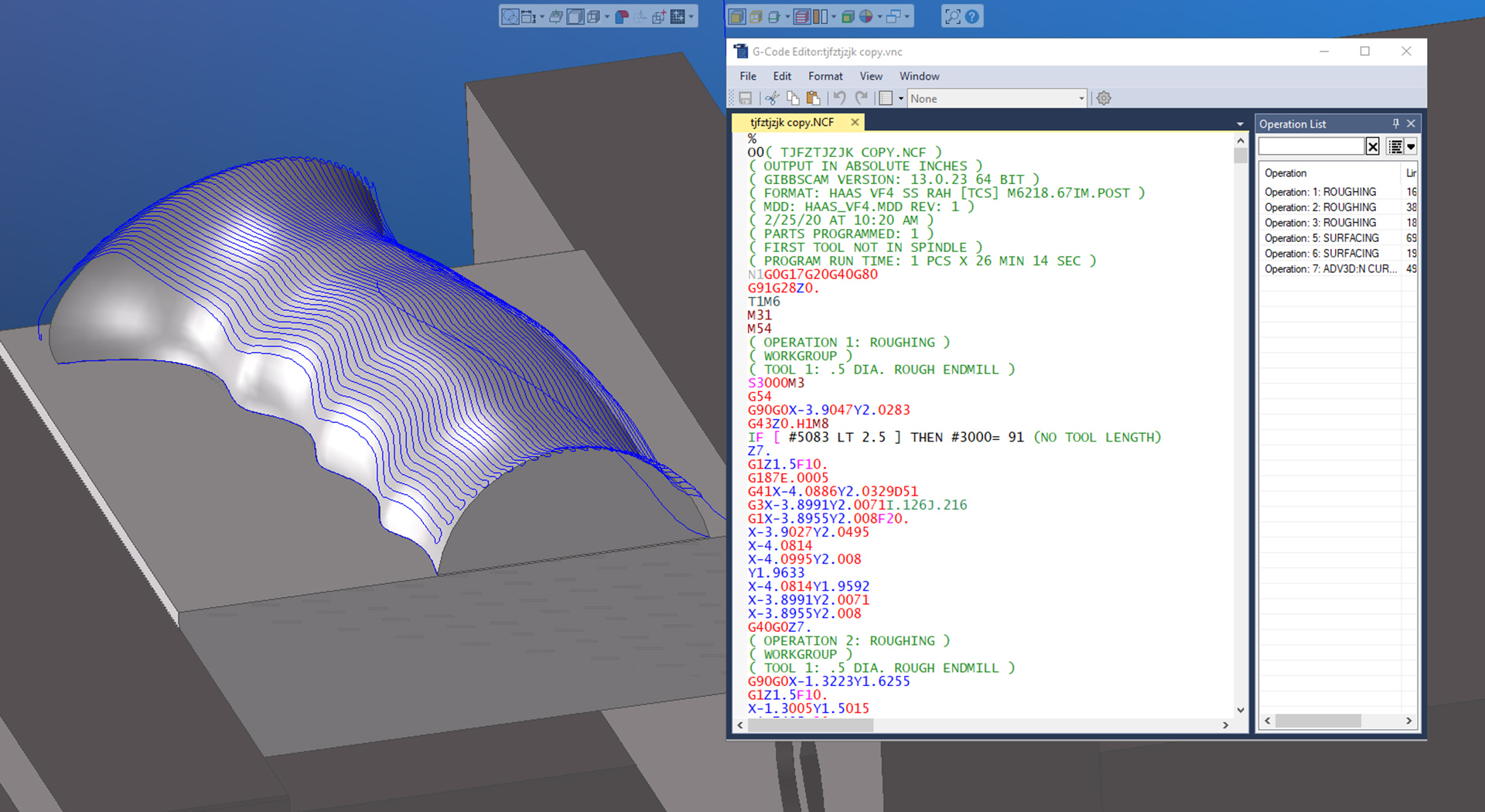

Quality Post Processors

A CAM system is only as good as the posted output. GibbsCAM has the largest library of factory created, error-free post processors on the market.

Watch a Full GibbsCAM Demo

See for yourself the power and flexibility of GibbsCAM in these comprehensive demonstrations of GibbsCAM Mill and Lathe.

GibbsCAM Milling On-Demand Demo

Explore the power of GibbsCAM Milling in this video demonstration. GibbsCAM’s full range of milling options provides you with the power and flexibility to program all your CNC mills with a single program and a single intuitive interface. Packed with powerful toolpath strategies for the most efficient CNC programs for 2 through 5-axis mills, GibbsCAM gives you the freedom to make your parts, your way.

GibbsCAM Lathe On-Demand Demo

Experience the power and simplicity of GibbsCAM Lathe in this video demonstration. GibbsCAM has a full range of turning options from simple 2-axis to Mill-Turn, to Multi-Task Machining (MTM), all using the same intuitive user interface. See how simple programming can be with GibbsCAM.

GibbsCAM Milling Solutions

GibbsCAM for 2 and 2.5 Axis Milling

GibbsCAM Production Milling delivers an easy to use CNC programming solution for shops that are cutting 2-axis features such as pockets, holes, and slots.

GibbsCAM for 3-Axis Milling

GibbsCAM 3-Axis milling creates smooth, accurate toolpaths for cutting complex shapes using either surfaces, solid models, or any combination of both.

GibbsCAM for Multi-Axis Milling

GibbsCAM Multi-Axis Milling uses state of the art toolpath strategies to generate accurate, reliable G-code for 4 and 5-Axis CNC machining centers.

GibbsCAM for High Speed Machining

Experience the advantages of GibbsCAM High Speed Machining! Both high feed milling, VoluMill, and VoluTurn toolpaths have many advantages over conventional roughing cycles, including dramatically shorter cycle time, longer tool life, reduction in part distortion, less horsepower required, less requirement on workpiece clamping, and better chip management.

GibbsCAM Turning Solutions

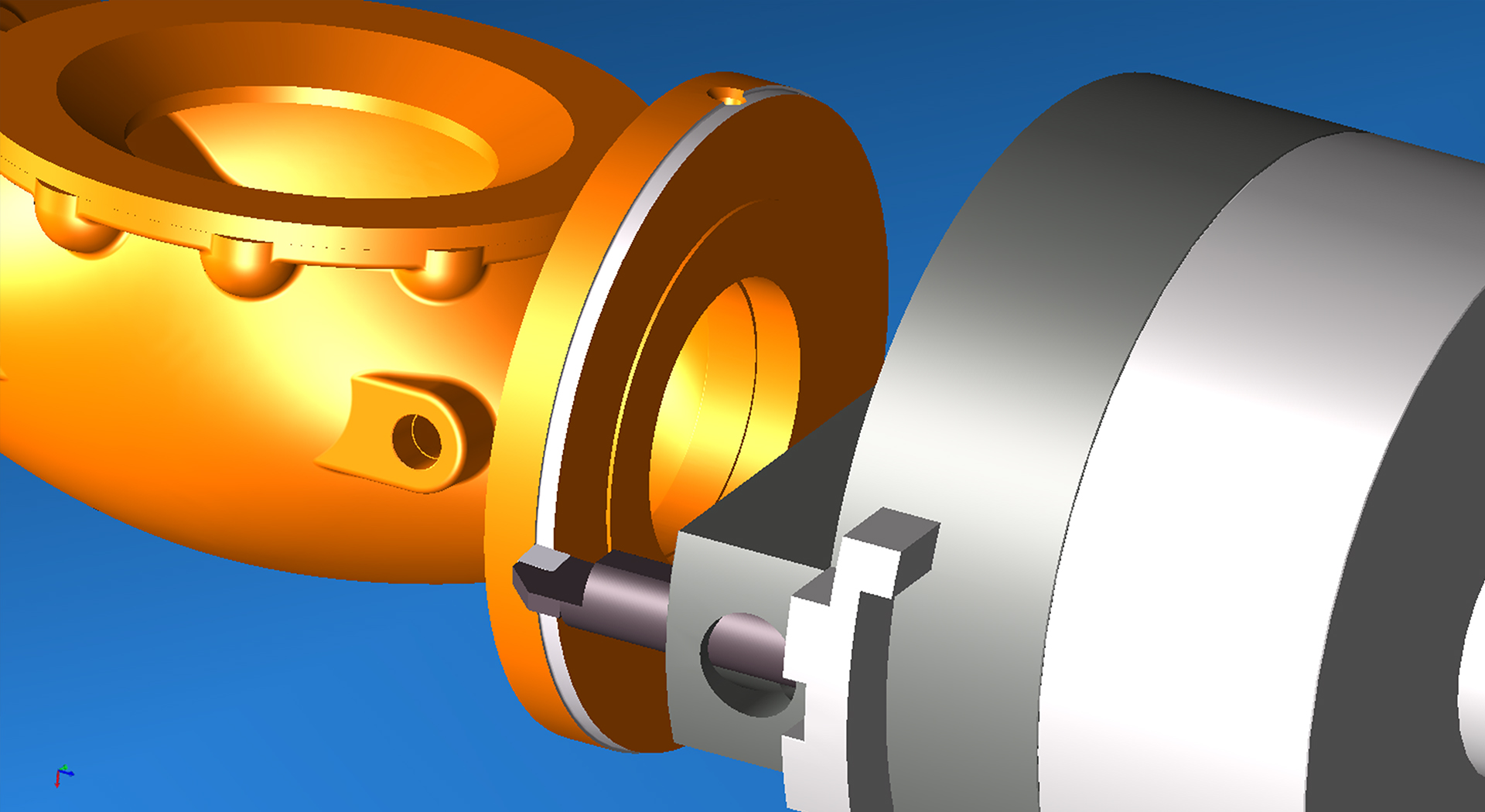

GibbsCAM for Turning and Mill-Turn

GibbsCAM Turning supports full 2-axis turning with a full range of toolpath strategies which makes programming lathes quick, easy, and efficient. In addition, by combining the milling and turning options, you gain mill-turn capability, with support for live tooling.

GibbsCAM for Multi-Task Machining (MTM)

GibbsCAM MTM is specifically designed to address the CNC programming requirements of the most complex machine tools that combine both milling and turning. GibbsCAM MTM provides powerful programming tools that are easy to learn and empower the programmer with the ultimate in flexibility and configurability.

GibbsCAM for Swiss Machining

GibbsCAM Swiss is the best tool to program complex, high precision parts on Swiss-style CNC machines. The simplicity of GibbsCAM within the comprehensive toolset takes the stress out of programming these specialized machines.

GibbsCAM Add-on Options

GibbsCAM Shopfloor Viewer

The GibbsCAM Shopfloor Viewer provides shop-wide access to part data and simulation. This read-only tool allows operators, managers, and quality teams to inspect parts, verify geometry, analyze toolpaths, and generate reports—all without risking unintended changes to toolpaths or g-code.

GibbsCAM for Wire EDM

GibbsCAM Wire EDM, powered by OPTICAM, is a powerful, proven, high-end solution to handle all your Wire EDM needs. It includes comprehensive feature recognition and solids machining capabilities, toolpath rendering and simulation, a detailed technology database, and post processors for all major wire EDMs.

GibbsCAM for Probing

GibbsCAM 14’s new Probing option enables you to graphically complete the entire manufacturing cycle within the GibbsCAM programming interface. In-process probing allows you to take measurements, inspect features, and confirm the accuracy of a part without taking it off the machine. On-machine probing eliminates costly and time-consuming machine downtime and part scrapping.

Tombstone Machining

GibbsCAM TMS (Tombstone Management System) was developed specifically to simplify and streamline the multi-part setup, programming, toolpath verification and post processing for tombstone machining. Within a single interactive graphic interface, the TMS dialog provides all the options and flexibility required for CNC programmers to specify and modify machining strategies and generate efficient, error-free G-code ready for your machines.

GibbsCAM for Turbomachinery: MultiBlade

GibbsCAM 5-Axis MultiBlade module is optimized for programming turbomachinery blade parts such as blisks, blings and impellers. Powerful toolpath strategies include 5-axis simultaneous roughing, hub finishing, and blade and splitter finishing, with automatic gouge checking on all toolpaths. MultiBlade has 90% of the capabilities of high-end turbomachinery software at 10% of the cost!

GibbsCAM for Porting

GibbsCAM 5-Axis Porting option optimizes machining for engine manifolds, throttle bodies, and any parts with tubular openings (or ports) that change shape and curvature from one end to the other. The software can automatically detect the spine curve through the port and align the toolpath accordingly.

ToolManageriQ

Easily manage a centralized library of tools, holders, fixtures, and supplier data right inside of GibbsCAM. Share the tool library across your entire shop for more informed tool choices by CNC programmers and easy access by the tool crib manager or process planner. Easily group tools by any criteria, including job number, machine type, or tool type for quick access of available tools.

30-Day Money Back Guarantee

We’re so sure you’ll love GibbsCAM that it comes with a full 30-day money back guarantee!

Ready for the Next Step?

Try GibbsCAM free for 30 days and find out how simple CNC programming can be.

Reach out to schedule a personal demonstration of GibbsCAM using your parts and your machines.

More Products to Improve Your Productivity

Streamline your entire workflow with these quality tested and recommended products:

SpaceMouse

Improving ergonomics and efficiency at your CAD workplace. Using a 3D mouse can prevent repetitive patterns of movement, making your workstation considerably more efficient and healthier.

SpaceClaim Design Software

Ansys SpaceClaim’s unique user interface, modeling technology and versatile tool set help you create and modify imported geometry — without the complexity associated with traditional CAD systems.

eNETDNC

eNETDNC is an Ethernet-based CNC data management system that provides flexible, secure, reliable, and cost effective data management, by allowing the user to connect CNC machine controls using an existing computer network.

ThreadTracer

ThreadTracer is a GibbsCAM plug-in that creates efficient machining operations of large and custom threads using standard turning tools. It is highly effective for production machining of custom thread forms, large buttress threads, rope threads, trapezoidal threads, and large cable drums.

Raster2Vector

A GibbsCAM plug-in that allows users to convert JPEG and BMP files into vector drawings inside of GibbsCAM.

ROPECAM

ROPECAM produces NC-code for any outer or inner diameter rope thread. Programming taper for the rope thread, the ROPECAM allows declivity for the rope thread profile.